CNC Machining Services

Machined prototypes and production parts in as fast as 1 day. Request an online quote today.

Certifications

ISO 9001:2015 | AS9100D | ITAR Registered

![]() Looking for a reliable, quick-turn supplier of machined plastic and metal components? With hundreds of CNC machines, our unmatched in-house capacity ensures your parts are shipped on-time, every single time. At Protolabs, our AS9100-certified CNC machining facilities are designed for both rapid prototyping and low-volume production of end-use components.

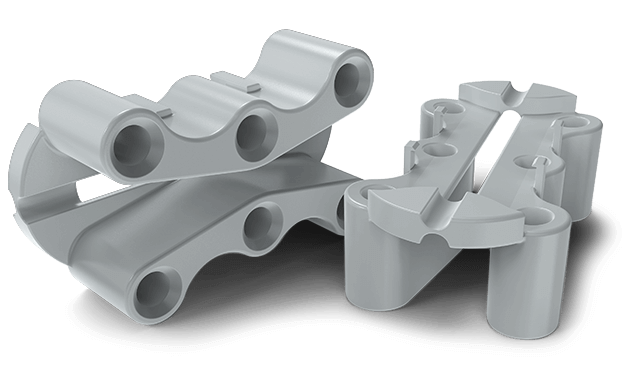

Looking for a reliable, quick-turn supplier of machined plastic and metal components? With hundreds of CNC machines, our unmatched in-house capacity ensures your parts are shipped on-time, every single time. At Protolabs, our AS9100-certified CNC machining facilities are designed for both rapid prototyping and low-volume production of end-use components.

CNC Machining Processes

CNC Milling

CNC milling is a subtractive manufacturing process that uses 3-axis milling and 5-axis indexed milling processes to cut solid plastic and metal blocks into final parts.

CNC Turning

CNC turning with live tooling combines both lathe and mill capabilities to machine parts with cylindrical features from metal rod stock.

CNC Machining Materials

Introducing Economy Lead Time

Now, we offer economy lead time options for machining projects that are less time-sensitive and more cost-competitive. Give it a try today by uploading a CAD model.

Why Choose Us for Custom CNC Machining?

Fast and Reliably Delivery

Iterate part designs quickly and accelerate product development with quick-turn parts. Our automated design analysis will help spot any difficult to machine features before your design is sent to the manufacturing floor and save you from costly reworks further down the product development cycle.

Manufacturing Analysis and Online Quotes

When you upload your 3D CAD file to request a quote, we'll analyze your part geometry to identify any features that may be difficult to machine such as tall, thin walls or holes that cannot be threaded.

Domestic Production and Support

Work with a trusted U.S.-based manufacturer and eliminate the risk of sending parts overseas. You can also call or email us at any time and we'll help with ordering parts, design feedback, material recommendations, and answer any questions.

Infinite Capacity

Eliminate downtime spent waiting for parts and safeguard in-house machining with on-demand relief and infinite manufacturing capacity.

Material Selection

We stock more than 30 engineering-grade plastic and metal materials that are suitable for various part applications and industries. Materials range from plastics like ABS, polycarbonate, nylon, and PEEK to aluminum, stainless steel, magnesium, and copper.

Tour Our Machine Shop (Virtually)

Take a quick tour through our 215,000 sq. ft. CNC machining facility in Minnesota to see how we manufacture parts in as fast as 24 hours.

Have Complex Components for Machining?

Tighter tolerances down to ±0.0008 in. (0.020mm). Complete parts with no material left behind. Anodizing at scale. Our manufacturing network of premium suppliers at Hubs can help. Get an instant quote for up to 1,000 parts today.

What's in an Online CNC Quote?

Upload a 3D CAD file of your machined part and within a few hours we'll send you manufacturing analysis and an interactive quote. Within your quote you can modify materials and quantities and see pricing updates in real-time. Additionally, within your manufacturing analysis, you can assign threading with a click of your mouse.

Each CNC quote contains:

- Real time, accurate pricing

- Manufacturing analysis

- Threading assignments

CNC Machining FAQs

How much does CNC machining cost?

Prices start around $65, but vary based on complexity, quantity and lead time. The best way to find out is to submit a 3D CAD model and get an interactive quote with design for manufacturability (DFM) feedback. Because we use proprietary software and automated fixturing processes, there are no up front non-recurring engineering (NRE) costs. This makes purchasing quantities as low as 1 to 200 parts cost effective. Prices compared to 3D printing are comparable to somewhat higher, but machining offers improved material properties and surfaces.

What types of threading options are available?

We offer UNF, UNC, and metric threads for machining along with coil and key inserts (but do not supply or install the inserts). These are available on both milled or turned CNC parts. View this page to see our complete threading options.

What is the maximum part size for CNC machining?

Maximum part size will vary based on your selected material. Our largest part size offered is 22 in. x 14 in. x 3.75 in. (559mm x 356mm x 95.25mm) and is available in Aluminum 6061 and 7075. View this table to see maximum dimensions by material.

Where can I learn more about CNC design?

We have a variety of resources on CNC machining and how to design parts for the process. Here are some of our favorites:

What are the advantages of CNC machining?

Product designers and engineers choose CNC machining to rapidly produce prototypes and production parts. The manufacturing technology offers a high level of precision, engineering-grade materials, quick-turn lead times.

Additional Links and Resources

How to Reduce CNC Machining Costs

CNC Machining Materials

What is CNC Machining?

Fine-Tuning Tolerances for CNC Machined Parts

Get an online quote and design analysis today.